The evolution of the Brose S Mag engine

A lot has happened to the Brose S Mag electric bike motor in recent years. Numerous upgrades are said to have significantly increased the service life of the electric bike motor. It's time to take another look at the Berlin unit!

Brose S Mag - modern electric bike motor with history

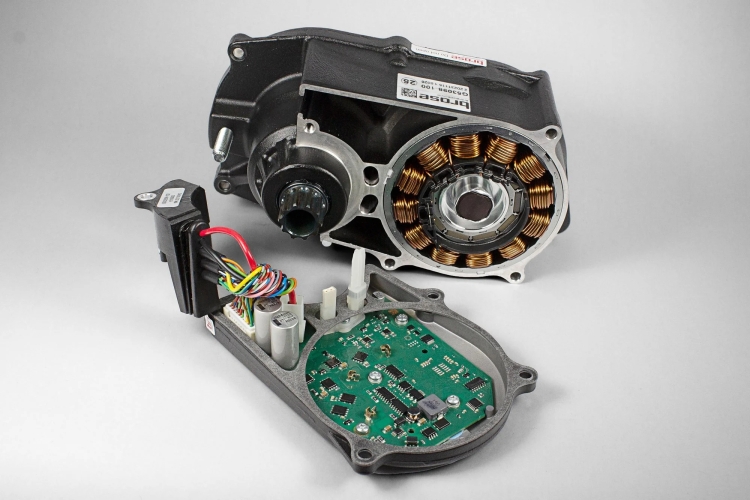

The Berlin brand's electric motor was the first e-bike unit to use a magnesium case. The main aim was to avoid the heavy weight of the units at the time.

But, as Brose also admits, the e-bike's motor was still struggling with some teething problems at the time. Over time, several upgrades were made to the power unit to improve the engine's reliability.

The Berlin-based company's first major optimization package began in 2021, which, according to its own statement, has resulted in greater engine durability. For example, the drive belt was replaced with a new, longer-lasting version. Other small but gradual improvements followed. In this way, the noise of the already quiet unit was further reduced and the engine was better protected against external influences, such as water ingress.

One of the initial problems with the first model was the belt, which could break. - This was replaced in the first major update of 2021 with a new version that promises significantly longer running times.

The use of new electronics and software has not only increased driving comfort. On the contrary, the modernized electronics ensure the long-term availability of spare parts and seamless integration into various e-bike systems. This is also reflected in the Brose Reman drives, in which the old S-Mag motors are remanufactured and given a new lease of life.

The electronics have also changed since the S Mag was introduced - the new components not only increase riding comfort, but also ensure the supply of spare parts for the future and integration into existing electric bike systems.

To check the suitability of the upgrades, Brose put them through an extensive endurance test in the Harz Mountains in recent years, which put them to the test over an impressive 50,000 kilometers and around one million meters of altitude. In addition, it is used on endurance test benches, where the engine completes around 175,000 hours of operation every year at the Berlin factory.

Share

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0

![[Originals] Back Pack or Hip Pack, which is better?](https://emtb.pt/uploads/images/202401/image_750x_65afc8c0e27c7.jpg)

![[News] Scott unveils new Ransom endurance bike](https://emtb.pt/uploads/images/202402/image_100x75_65be4dd2e2a89.jpg)

![[News] New Merida eOne-Forty and eOne-Sixty eMTBs share looks and suspension with non-assisted siblings.](https://emtb.pt/uploads/images/202403/image_750x415_65e1fe1795a95.jpg)

![[Originals] Geotour Aldeias de Xisto 2024 - An epic adventure](https://emtb.pt/uploads/images/202402/image_750x415_65df2c5ce7d04.jpg)

![[Originals] Battery - the basics of use](https://emtb.pt/uploads/images/202402/image_750x415_65c78a9b57546.jpg)

![[Community] The Supermarket Bike Adventure on the Alentejo Coast in 2011](https://emtb.pt/uploads/images/202402/image_750x415_65be54dc67979.jpg)

![[Video] Micro Bike Challenge Monsanto 2024 (Teaser)](https://img.youtube.com/vi/RP5JMl1UITk/maxresdefault.jpg)

![[News] Renthal expands into the pedal market with Revo-F](https://emtb.pt/uploads/images/202402/image_750x415_65ce33e6b17a2.jpg)

![[News] Scott unveils new Ransom endurance bike](https://emtb.pt/uploads/images/202402/image_750x415_65be4dd27d99b.jpg)